Very clever and well done!

I like when you can find the right tool for the job.

I like when you can find the right tool for the job.I have to cut some foam for a microphone case soon..... This little tip will come in handy.

| WaGuns.org https://waguns.org/ |

|

| My experience on cutting pelican case foam https://waguns.org/viewtopic.php?f=48&t=21446 |

Page 2 of 3 |

| Author: | never_to_much [ Tue Apr 02, 2013 2:35 am ] |

| Post subject: | Re: My experience on cutting pelican case foam |

And I just used a razor blade...... Dammit should a made a hot wire. That's really nicely done |

|

| Author: | milowebailey [ Tue Apr 02, 2013 5:55 am ] |

| Post subject: | Re: My experience on cutting pelican case foam |

Very clever and well done!   I like when you can find the right tool for the job. I like when you can find the right tool for the job.I have to cut some foam for a microphone case soon..... This little tip will come in handy. |

|

| Author: | delliottg [ Tue Apr 02, 2013 10:51 am ] |

| Post subject: | Re: My experience on cutting pelican case foam |

Hyiuheehee wrote: I nominate for sticky! I second that, this is a great post. |

|

| Author: | tigershark [ Wed Apr 03, 2013 8:07 am ] |

| Post subject: | Re: My experience on cutting pelican case foam |

I must say, that is professional work. Very impressive.  It would make a nice presentation case for a gun maker's product. |

|

| Author: | TacticalAssault [ Wed Apr 03, 2013 2:46 pm ] |

| Post subject: | Re: My experience on cutting pelican case foam |

Sticky'd by request. |

|

| Author: | brian [ Tue Jan 14, 2014 9:33 am ] |

| Post subject: | Re: My experience on cutting pelican case foam |

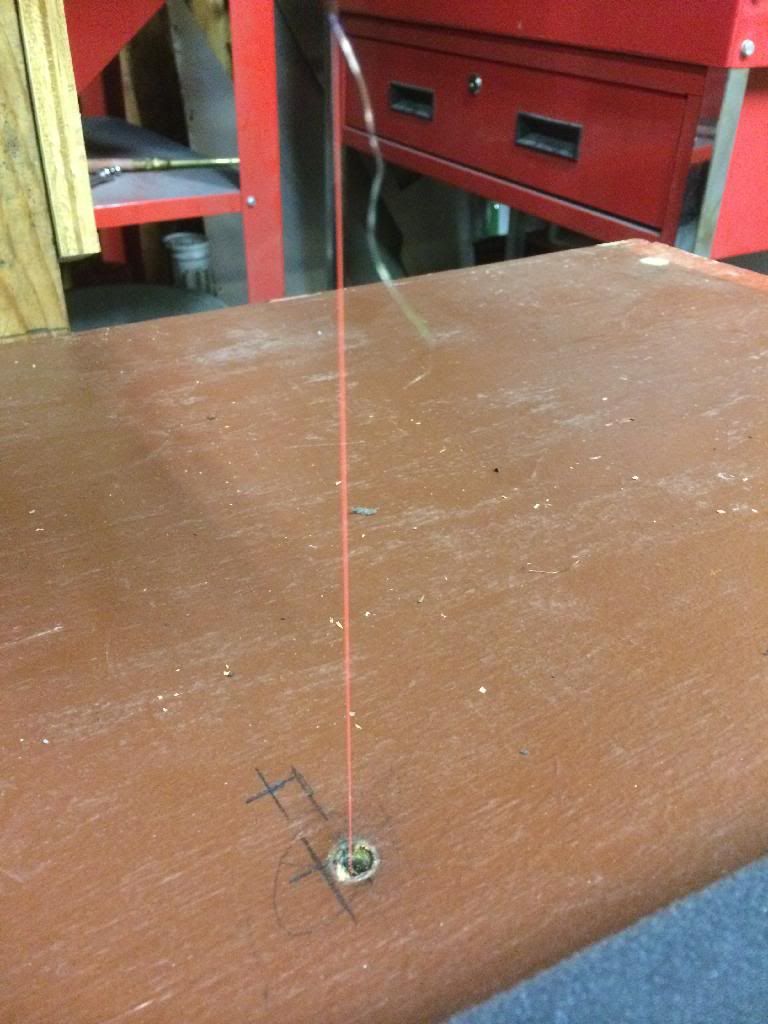

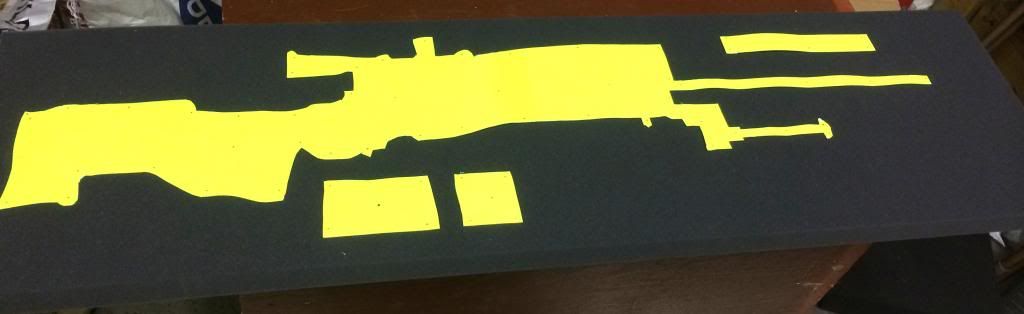

Well, the power supply I was using gave up the magic smoke, and all of the following ones I used just kept popping. cmica asked me to cut out foam for him, so it was time to upgrade the power supply. A variable power transformer was just the ticket, gives me complete control of the temperature of the wire.   Cmica's foam

|

|

| Author: | cmica [ Tue Jan 14, 2014 9:43 am ] |

| Post subject: | Re: My experience on cutting pelican case foam |

thank you Brian thank you Brian

|

|

| Author: | brian [ Tue Jan 14, 2014 9:49 am ] |

| Post subject: | Re: My experience on cutting pelican case foam |

You're welcome Chris  I'll be in tacoma tomorrow afternoon (2pm ish) if you're available. shoot me a text and we'll find a time to get it back to you

|

|

| Author: | RusoArmo [ Tue Jan 14, 2014 7:27 pm ] |

| Post subject: | Re: My experience on cutting pelican case foam |

CMICA, I hope you know by law you are required to post photographs of that foam with the sexies that fill it...... |

|

| Author: | brian [ Tue Jan 14, 2014 7:32 pm ] |

| Post subject: | Re: My experience on cutting pelican case foam |

Rusoarmo wrote: CMICA, I hope you know by law you are required to post photographs of that foam with the sexies that fill it...... I'll be sure add that verbiage to the signed contract

|

|

| Author: | mustangfreek [ Wed Jan 15, 2014 12:15 am ] |

| Post subject: | Re: My experience on cutting pelican case foam |

Nicely done, this is something i need to do one of these days also. |

|

| Author: | cmica [ Wed Jan 29, 2014 3:43 pm ] |

| Post subject: | Re: My experience on cutting pelican case foam |

Rusoarmo wrote: CMICA, I hope you know by law you are required to post photographs of that foam with the sexies that fill it...... OK, ok hang on to your britches, here comes the pic. Do want to say brian did an awesome job.  To me the hardest part was doing the tracing and and then using a compass divider to keep that 1/8" inside cut then using ball needles about every 4" to keep the poster board down, more where the sharper corners were like the bipod area. Once again thankyou! To me the hardest part was doing the tracing and and then using a compass divider to keep that 1/8" inside cut then using ball needles about every 4" to keep the poster board down, more where the sharper corners were like the bipod area. Once again thankyou!

|

|

| Author: | MadPick [ Wed Jan 29, 2014 3:46 pm ] |

| Post subject: | Re: My experience on cutting pelican case foam |

Holy hell, that's a damned near net fit. |

|

| Author: | Ball Shtuck [ Wed Jan 29, 2014 4:35 pm ] |

| Post subject: | Re: My experience on cutting pelican case foam |

brian wrote: Massivedesign wrote: Is there anything you can't cut? The list just got shorter  You iz smart Brian!! I never would have thought of something like that! Can you build a laser to do it next time? LOL. |

|

| Author: | deadshot2 [ Thu Jan 30, 2014 11:39 am ] |

| Post subject: | Re: My experience on cutting pelican case foam |

Good looking work. Something that works well to heat the wire is an old soldering gun. Just use a couple of #12 household wires stripped from some romex to run to your hot wire. Some of these "guns" have high/low settings. Someone else posted a neat way to cut foam without templates yet still have a neat looking job. Just do the layout in a "Mirror Image", ie butt of rifle to left if you want to end up with it to the right. Then trace all your items with a sharpie, holding it as vertical as possible. Cut the foam and then reverse it in the case. All the sharpie marks are now underneath and the top is clean. I recently did a case for my rifle and found "The Foam Factory" to be a great source. Delivered to my door in a compressed package. Expanded to full size the next day. http://www.thefoamfactory.com/ |

|

| Page 2 of 3 | All times are UTC - 8 hours |

| Powered by phpBB® Forum Software © phpBB Group https://www.phpbb.com/ |

|